Oct 27th 2020

SIPA Xtreme- Revolutionising PET Preform Production

Xtreme by SIPA is an innovative technology used to manufacture PET preforms with high flexibility and efficiency. Not only can these systems use virgin materials but also 100% recycled materials to reduce waste and your carbon footprint.

Xtreme Renew

In collaboration with EREMA, the SIPA Xtreme Renew system processes washed flakes of recycled PET into preforms within the same machine, reducing costs, protecting the environment and producing a wide range of food-grade PET.

The advantages:

- 10% lighter PET containers

- Save 30% on energy

- Up to 15% lower TCO compared to conventional recycling

- 60% less carbon dioxide emissions

- 100% sustainable

The Process…

- Decontamination- Improves the quality of the melt and therefore the final product.

- Extrusion– Enters into a high vacuum with a low residual moisture, which cuts extruder length, costs and improves colours.

- Filtering– Dependent on the final application, the resin is filtered through a particular sized mesh. The filter pack also consists of a self-cleaning system to improve longevity.

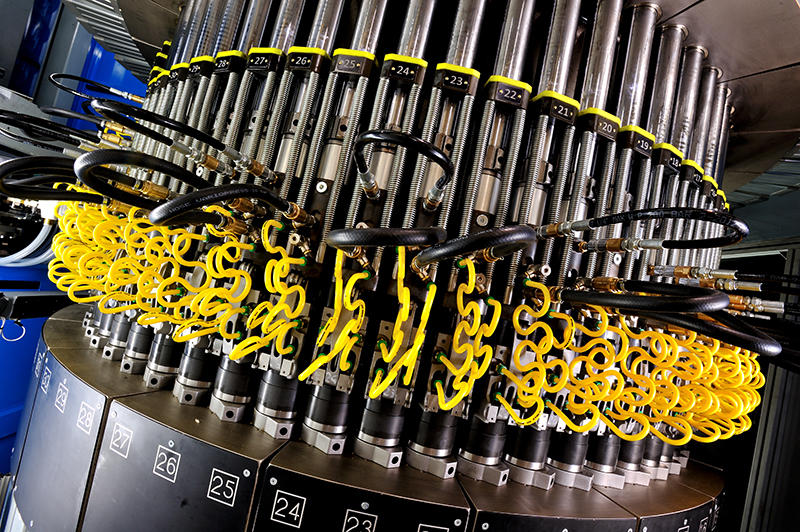

- Rotary Injection-Compression- Modular design of the wheel with a gentle material treatment and quick format change over.

- Preform Cooling– Consists of a cold air jet on the internal and external preform surfaces. There is also the option to include quality inspection and reject non-compliant preforms, suing 5 optical cameras.